Our Location

304 North Cardinal St.

Dorchester Center, MA 02124

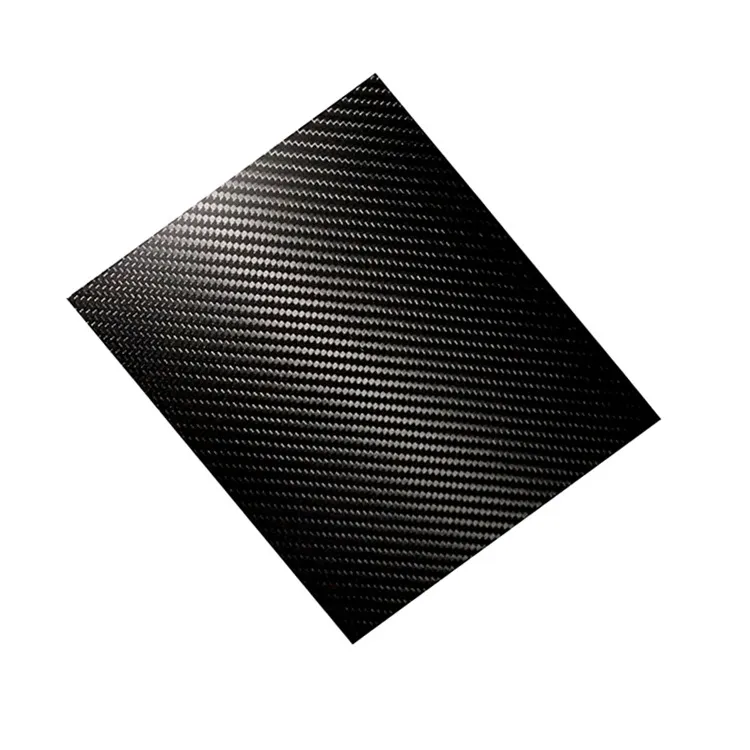

The history of carbon fiber is complex, but the big takeaway is this — modern carbon fiber hasn’t been around for very long. The first versions of the material were extremely weak, especially by today’s standards. On top of the material’s poor physical qualities, the complexity of production made it cost-inefficient to produce on a broad scale until the late 1960s.

When the technology became available, there were a few key industries that picked it up quickly:

Military: The military was the first industry to use carbon fiber in a significant capacity. This started with the U.S. Navy, which utilized incandescent lightbulbs with carbon fiber filaments due to their resistance to ship vibrations. The military also funded a great deal of Union Carbide’s early research into rayon-based carbon fibers, utilizing the results for rocket and aircraft components. After the development of stronger carbon fibers, the military quickly latched on to the material in a greater capacity.

Aerospace: The aerospace industry was one of the first industries to adopt carbon fiber. Starting with Rolls Royce’s carbon fiber compressor blades in jet engine assemblies in the 1960s, the aerospace industry quickly began looking into carbon fiber as a replacement for aluminum and titanium in certain types of components. Much of this interest was due to the superior strength-to-weight ratio of carbon fiber compared to other metals.

Sporting goods: British researchers in the mid-1960s developed PAN-based carbon fiber that featured high strength compared to weight. Manufacturers quickly capitalized on these properties, and British companies produced some of the first carbon fiber golf clubs, tennis rackets, and skis.

From these humble beginnings, carbon fiber applications quickly grew as the material was researched and developed and production costs decreased.

Today, a new application for carbon fiber seems to appear every day. While half a decade ago carbon fiber was exotic and expensive, you can now find carbon fiber in a huge range of industries and applications. Just a few uses of carbon fiber include:

Automobiles: Carbon fiber has been adopted rapidly in automobile manufacturing. The material first found its use in Formula 1 and NASCAR vehicles due to its strength-to-weight ratio, which helped develop faster cars. The material also gained traction in the production of high-end cars due to its sleek, high-tech look. As costs come down, carbon fiber is expected to be used in components for mass-produced cars, such as housings and frames.

Aerospace: Aerospace was one of the first industries to adopt carbon fiber due to its strength and weight savings, and they’ve made good use of the material. In fact, 30% of all carbon fiber is used in the aerospace industry. From spacecraft and aircraft to helicopters and gliders, carbon fiber is everywhere in the modern aerospace industry.

Sporting goods: Carbon fiber is everywhere in sports goods due to its strength and lightweight. In fact, carbon fiber is often seen as a top-tier material for professional sports. Hockey sticks, tennis racquets, archery bows, and golf clubs made from carbon fiber are often used in competitions, while carbon fiber rowing shells and bicycles are the new standards. Even clothing and protective gear are made with carbon fiber, with racing sports often using carbon fiber helmets and shoes.

Medicine: The medical field is another industry where carbon fiber has made significant headway in recent years. Carbon fiber shows up as transparent on X-ray images, which has led to its use in a wide range of X-ray and imaging equipment. Carbon fiber is also used in prosthetic limbs, which are strong, light, and comfortable to wear and use.

On top of broad industry applications, carbon fiber is gaining traction as a material for in-home and DIY uses. Carbon fiber is an eye-catching material for furniture, utensils, helmets, phone cases, and even statement clothes. These days, it’s easy to find pre-made or ready-to-assemble kits so anyone can have or make their own carbon fiber accessories.

From www.iyrs.edu